Gummy is a kind of candy that everyone likes to eat very much. It tastes very chewy and elastic. It can be chewed for a long time. It can relax a lot by eating a piece of gummy for entertainment or busywork. So now the sticky is in the adults. China is more popular and even used to share when meeting to expand the circle of friends.

The public has widely welcomed such a delicious candy, and many people are also curious, what kind of raw materials are used to form such a rich taste?

what are gummies made of?

The professional technical article of the highest quality soft candy production equipment in 2021 shows that smooth candy production is more complicated. Suppose you want to make high-quality soft candy. In that case, you need to use relatively high-quality raw materials, such as white sugar, glucose syrup, and starch—flavoring agents, food coloring, citric acid, and gelatin, etc. Due to different recipes, the fudge made is also extra.

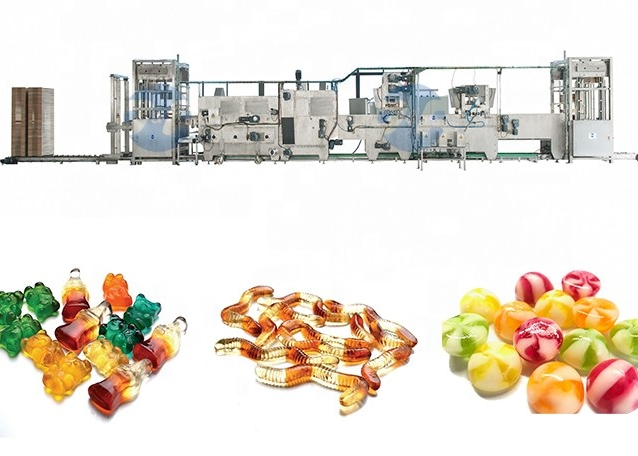

When manufacturers produce soft candies, in addition to using high-quality formulas and raw materials, they also need to use high-quality production equipment. Equipment, to a large extent, will affect the quality and efficiency of the production of soft candies. The gummy machine is one of many well-known manufacturers. Professional equipment used.

The specific production process of soft candy is as follows:

First, place the prepared ingredients in a dissolving cooker according to the fudge recipe, and then heat it for about 15 minutes to slowly boil it into a syrup state.

Next, these syrups are transported to the mixer for flavoring, adding edible vegetarian food and flavors, etc., and mixing them evenly to make them into different flavors. Then pour these finished materials into the mold. To prevent adhesion, the mold is usually sprinkled with some starch. If you want to make different gummy shapes, you can use different molds, such as bear shape and worm shape.

After that, these molds are transported to the cooling equipment for cooling and left to stand for about 24 hours. After the soft candies are solidified, they are demolded, and then the finished soft candies are transported into the rotating drum. The soft cans can be removed during high-speed rotation. The residual starch on the surface of the sugar makes the soft candy more crystal clear.

Finally, the packaging machine is used for packaging, and the production is completed.

The above is the specific production process of soft candies. The use of high-quality equipment can realize automatic production, and even without production experience. It can produce soft candies with stable quality.

The gummy making machine is our very high-selling food machine. Now it has been exported to many countries and regions worldwide, helping many companies expand the market. The equipment is reliable in quality and stable in performance. And the soft sweets produced are widely recognized by consumers. Good quality and low price are our tenets when we make equipment, and helping customers succeed is our goal.

We look forward to achieving a win-win situation with more partners!