When we walk into supermarkets or shopping malls, in the food section, we often see a wide variety of soft candy, with a wide range of types and exquisite packaging, including bagged, bulk, gift boxes, and so on. Gummy is a prevalent snack food because of its delicious chewy, small and cute, easy to carry, etc.

The gummy sold in the market has to be processed by the gummy bear machine, after a series of production processes to make delicious candy for sale finally. Generally speaking, the last process of gummy production is packaging, and there are more bags of gummy, and there are large and small bags, which contain different amounts of candy.

how many gummy bears are in a 8 oz bag?Before answering this question, let’s understand the concept of ounce firstly. The ounce is both a unit of weight and a unit of capacity.

The concept of ounces:

1, constant troy ounces: the unit of weight. The overall abbreviation for oz. av. 1 ounce = 28.350 grams 1 ounce = 16 dram (dram) 16 ounces = 1 pound (pound) .

2, medicine troy ounce: the unit of weight. The overall abbreviation for ap oz. 1 ounce = 31.1030 grams.

3, fluid ounce: the unit of volume measurement. The symbol for oz. 1 imperial fluid ounce = 28.41306 ml, 1 U.S. fluid ounce = 29.57353 ml.

Through the above simple introduction, we must have a specific understanding of the concept of ounces. Due to the shape of candy, the size varies, so the number of gummy contents in the bag is not fixed, mainly dependent on gummys’ shape.

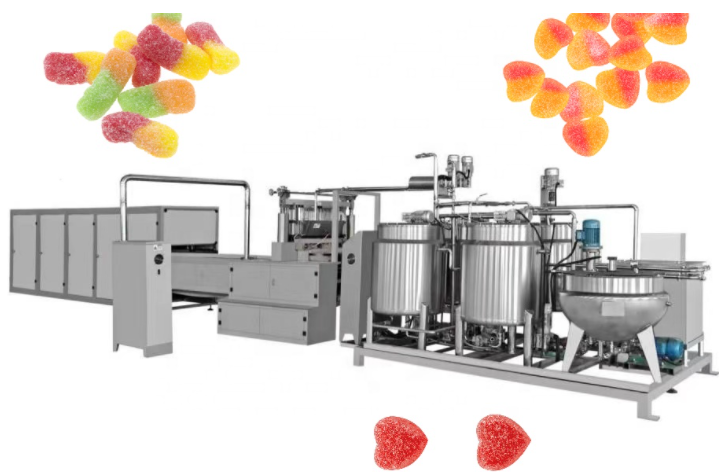

Packaging is a process of gummys’ processing, and the most important thing is the production of gummies. Let’s take a look at the whole process of gummy processing, and see the characteristics of the gummy bear making machine and how does it work?

Features of the gummy bear making machine:

1、PLC/computer process control available.

2, LED touch screen, easy to operate.

3、The main part is made of stainless steel.

4, the linear structure is simple, easy to install and maintain.

5、Pneumatic components, electrical components, operating components are used the world’s advanced brand-name components.

6、 High-pressure double crank control mold opening and closing.

7、High degree of automation in operation, high degree of intelligence, no pollution.

8、Using a connector to connect with the air conveyor, it can be directly connected with a filling machine in series.

9、Using automatic steam control system instead of the manual steam valve to control the stable steam supply of microfilm pot.

Composition of the gummy production line:

The gummy production line mainly consists of various parts such as an automatic weighing and stirring system, dissolving tank, microfilm pot, precipitator, cooler, etc. It is controlled by an advanced servo system, which is simple and convenient to operate and can be used for multiple purposes.

Flow chart of soft candy production line:

Sugar and gelatin dissolution → mixing → cooling → transportation → deposition → cooling → demolding → subsequent treatment → packaging

This machine is a candy production machine with extensive applications, producing various high-quality and uniform candies, soft and hard candies, lollipops, toffees, etc. Gummy making machine is the ideal candy pouring equipment to produce smooth and transparent candy. Gummy making machine is the ideal equipment for producing high-quality products and an advantage for candy manufacturers to pass GMP, HACCP, and QS certification easily.

We are a modern enterprise specializing in the R&D, manufacturing, and sales of candy machinery and baking equipment. In order to better meet the needs of customers better, we actively explore, through continuous research, developed a more high-quality performance of the gummy machine. Once the product is sold, it is recognized by the majority of users. In addition to the domestic market, the equipment has been widely sold to Europe, North America, South America, Africa, and other countries.

The company has passed the ISO9001 quality management system certification, and some products have passed the EU CE test and obtained CE certificate. We have our own intellectual property rights and professional engineers and have been to many countries to install, debug, and test many equipments. In addition, we have new condition molds that can be connected to increase the output. Please trust our products. We will provide efficient machines and excellent service. If you are interested in our machines, please contact us.